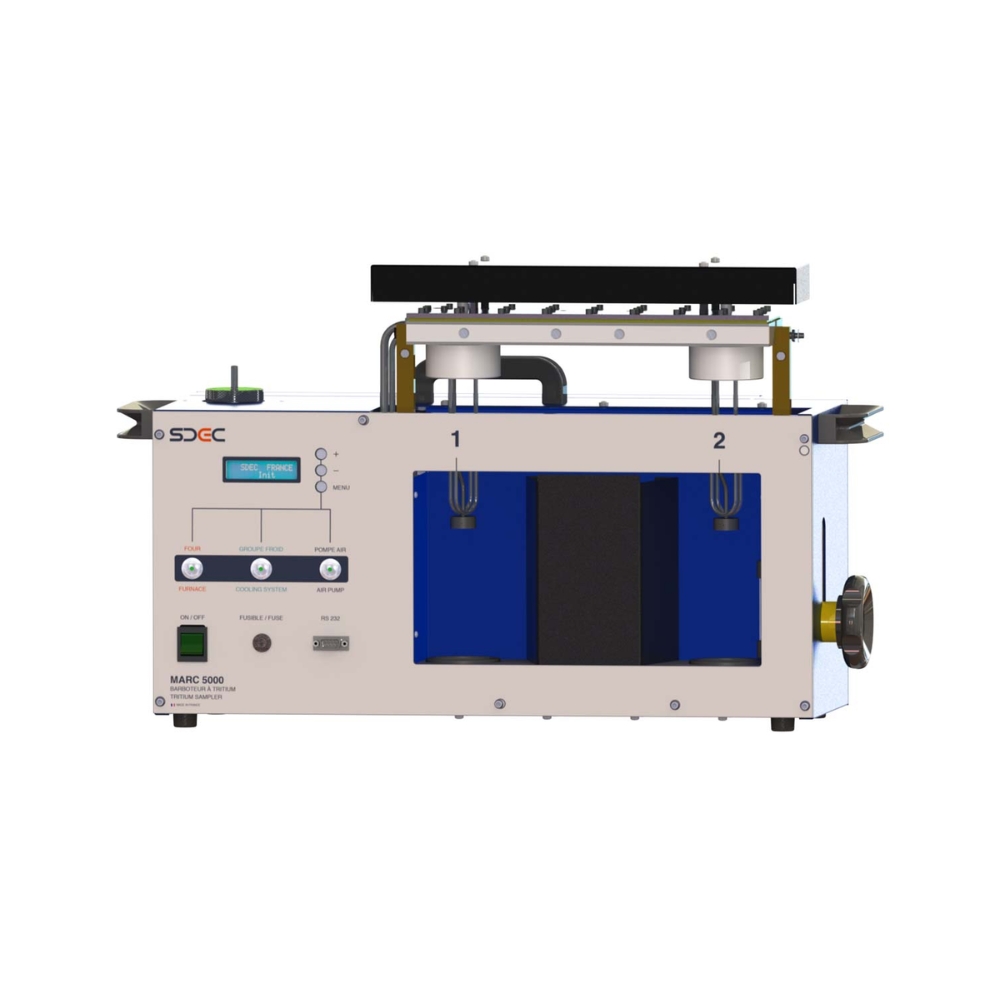

MARC 5000 – Tritium Bubbler: Dual Pot Atmospheric Monitoring System (Without Oven) for Trapping Tritium in HTO Form

- EFFICIENCY: Precise monitoring of atmospheric Tritium (HTO only) with optimal trapping efficiency, suitable for long periods of activity thanks to its innovative cooling system (optional).

- VERSATILITY: Usable in various sectors, including nuclear power plants and nuclear medicine.

- AUTOMATIC REGULATION: Automatic adjustment of airflow based on pressure loss.

- PERFORMANCE: Regulated air flow, durable pump, and 316L stainless steel circuit.

- PRECISION: Particle filtration and real-time display of airflow/volume.

- SAFETY: Visual and remote alarms, with anomaly recording.

- RECOGNITION: Endorsed by renowned institutions such as IRSN, the French Navy, EDF, ANDRA, and CEA.

- CERTIFICATION: NF ISO 20045 & NF ISO 20041-1

| APPLICATIONS |

|

·Nuclear Power Plants ·Industrial Use of Tritium ·Research on the Impact of Different Contamination Levels ·Nuclear Medicine |

– Tritium Bubbler Comparison –

This comparative table details the specifics and characteristics of tritium bubbler systems, highlighting the MARC 5000 model with 2 pots (without oven) and the MARC 7000 model with 4 pots (with oven).

| Tritium Bubbler - Marc 5000 | Tritium Bubbler - Marc 7000 | |

|---|---|---|

|

|

|

| Trapped form of tritium | HTO only | HTO, HT and OBT |

| Nº of pots | 2 | 4 |

| Trapping yield (HTO) | HTO = 99% +/- 7% | |

| Optimized trapping yield (HT) | ❌ | Furnace efficiency HT>HTO = 98 +/- 11% |

| T° furnace temperature | ❌ | 200 à 500°C |

| T° trapping solution | Optional | 7°C (for an ambient temperature of 20°C) |

| Weight (kg) | 15kg (without cooling) 27kg (with cooling) | 29kg |

| Max. Power (Watts) | 260 | 700 |

| Air Flow | ✅ | ✅ |

| Nomalization conditions | ❌ | ✅ |

| Sampling Duration | ✅ | ✅ |

| Volume of air sampled | ✅ | ✅ |

| Cold circuit temperature | ✅ | ✅ |

| Oven temperature | ❌ | ✅ |

| Standardized flow meter | 10 à 50 Nl/h | |

| T° of use | +2 à +45 °C | |

| Storage tº | -5 à +70 °C | |

| Adjusting the flow normalization temperature | 0 à +25ºC | |

| Display | Backlit LCD screen | |

| Dimensions L x H x P (mm) | 700 x 356 x 270 | |

| Footprint (mm) | 1000 x 600 x 530 | |

| Power Supply | 230 V / 50 Hz IEC plug (or 120 V / 60 Hz IEC plug) | |

| Electrical protection | differential circuit breaker (sensivity = 30mA) | |

| Air flow regulation | Automatic | |

| Other features | Reset function for duration and volume before re-sampling | |

| Audible alarm in the event of faults during sampling and display of the fault sequence on the screen | ||

| Memorization of the last 8 faults, data recoverable via the RS 232 output | ||

| Remote reporting of faults | ||

– Operating Principle –

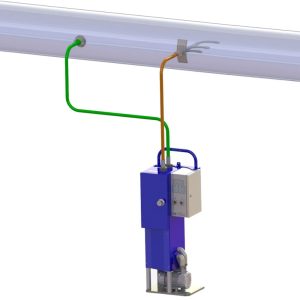

The MARC 5000 captures tritium in water vapor form (HTO) using the bubbling principle in two bubbling pots, with prior filtration of particles in the air. After sampling, the tritium activity in the water from the bottles is measured later by liquid scintillation counting. The measured tritium activity is converted into volumetric activity in the air (in Bq/m3), based on the volume of air treated by the device.

This model is equipped with a cooling circuit that maintains the trapping solution at an average temperature of 7°C (in a 20°C environment), thus preventing the evaporation of the sample solution. This feature is crucial for samplings over a week or longer.

– Performance –

(CEA Marcoule test report June 2006)

– Air Flow Process –

A pre-filter paper at the entrance (∅ 45 mm) prevents dust aspiration, and the electronic flow meter is protected by Gortex® filters. The air flows in glass vials (250 ml capacity) through stainless steel air tubes. The airflow can be adjusted from 10 to 50 liters per hour, regulated by a certified flow meter.

– Official Supplier –

Various nuclear power plants in Europe and worldwide.

– About SDEC –

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

– FAQ –

Yes, you can customize the Marc 5000 according to your needs. You can choose the Marc 5000 with or without a cooling unit. Additionally, you can add the following options to the bubbler: TOR Arte – Alarm Relay: Type T.O.R, Luminous Alarm Option, Pressure Regulator, JBUS Protocol.

In some cases, the radionuclide does not exist in its organic form and it is unnecessary to attempt to sample it.

The pressure regulator is primarily used when the bubbler is connected to a pressurized device.

The device is equipped with a cooling circuit that maintains the trapping solution at an average temperature of 7°C (for an ambient temperature of 20°) and thus prevents the loss of the sample solution by evaporation. This option is essential for weekly or longer duration sampling.

Additional information

| Trapped form of tritium | HTO |

|---|---|

| Weight | 27 kg (with cooling group) |

| Dimensions | L x H x P = 700 x 356 x 270 mm |

| Footprint | 1000 X 600 X 530 mm |

| Temp operating | +2°C à +45°C |

| Temp storage | -5°C à +70°C |

| Power | 260 Watts |

| Power Supply | 230 Volts 50 Hz IEC plug (or 110 Volts 60 Hz) |

| Electrical protection | 6A time delay fuse |

| Applications | Industrial Use, Nuclear Medicine, Nuclear Power Plants, Research on the Impact of Different Contamination Levels |

| Extras | monocoque in aluminum alloy |

| Housing paint | compliant with decontamination |

| Air flow Regulation | 10 to 50 L/h |

| Display | Backlit blue LCD screen |

| Integrated system for reporting faults | Repeated acoustic signal with fault display on the screen. |

| Cooling | With cooling group, Without cooling group |

| Options | Without options, Discrete card – Alarm relay, Light alarm option, Pressure regulator, JBUS protocol |

Reviews

There are no reviews yet.