- Catalogue

- Applications / Produits

- AIR ET GAZ

- EAUX SOUTERRAINES

- EAUX DE SURFACE

- SOLS

- BOUES ET SÉDIMENTS

- MÉTÉO

- VÉGÉTATION

- MATÉRIAUX

- Solutions

- Agricultures

- Aquaculture

- Construction et infrastructure

- Diagnotic sites et sols pollués

- Eau en milieu naturel

- Eau potable

- Golf et aménagement paysager

- Ingénierie hydrogéologie

- Littoral et côtier

- Matériel de laboratoires

- Nucléaire et démantèlement

- Pilotage de l’irrigation

- Prélèvement d’air

- Process Industriel

- Mines et carrières

- Recherche agronomique et environnementale

- Marques

- Service et locations

- À propos de SDEC

- Ressources

- Distributeurs

- Langue

- Contactez-nous

Pompes péristaltiques PRO et ROYAL

L’échantillonnage

de terrain

n’a jamais été

aussi simple

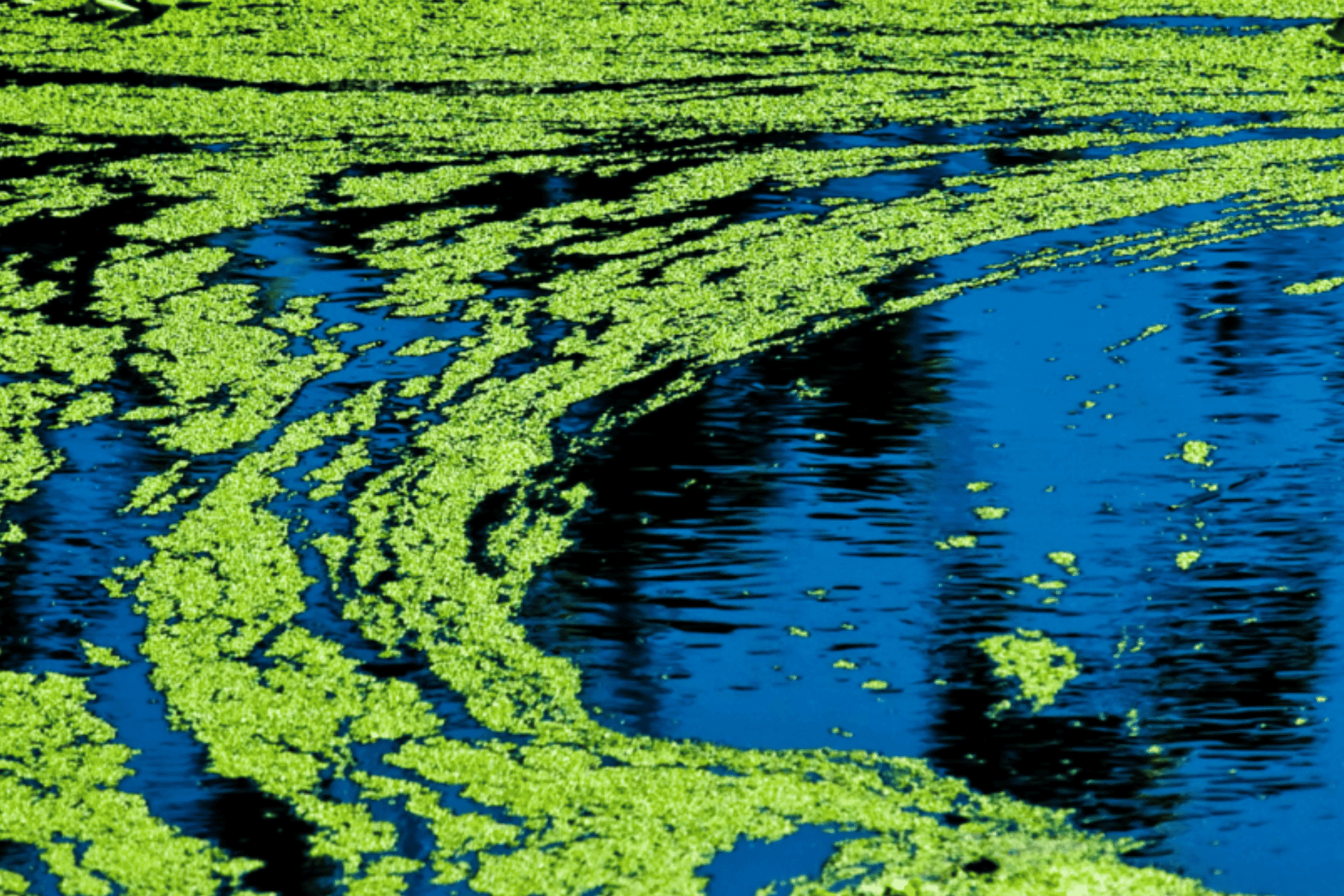

Alerte précoce pour la prolifération d'algues nocives

Surveillance

efficace

des algues

bleu-vert

Produits de pointe et service exceptionnel.

Plus de 30 années d'expertise

et innovation pour un

environnement protégé

Les technologies logicielles les plus puissantes

Logiciels pour les

investigations

hydrogéologiques

et la conformité

Stations météo autonomes

Enregistrez de façon

fiable et économique

jusqu'à 6 paramètres

environnementaux

Fabricant et distributeur

Offrant une gamme complète pour la surveillance de l'air, de l'eau et du sol, nos produits et partenariats reflètent notre expertise et innovation.

Plus de 30 ans d'expertise

SDEC vous accompagne dans vos besoins de mesure, de prélèvement et de surveillance environnementale.

Petites et moyennes séries

SDEC dispose d’un binôme ingénierie & production expérimenté avec un savoir-faire et des moyens à même de répondre à des demandes complexes.

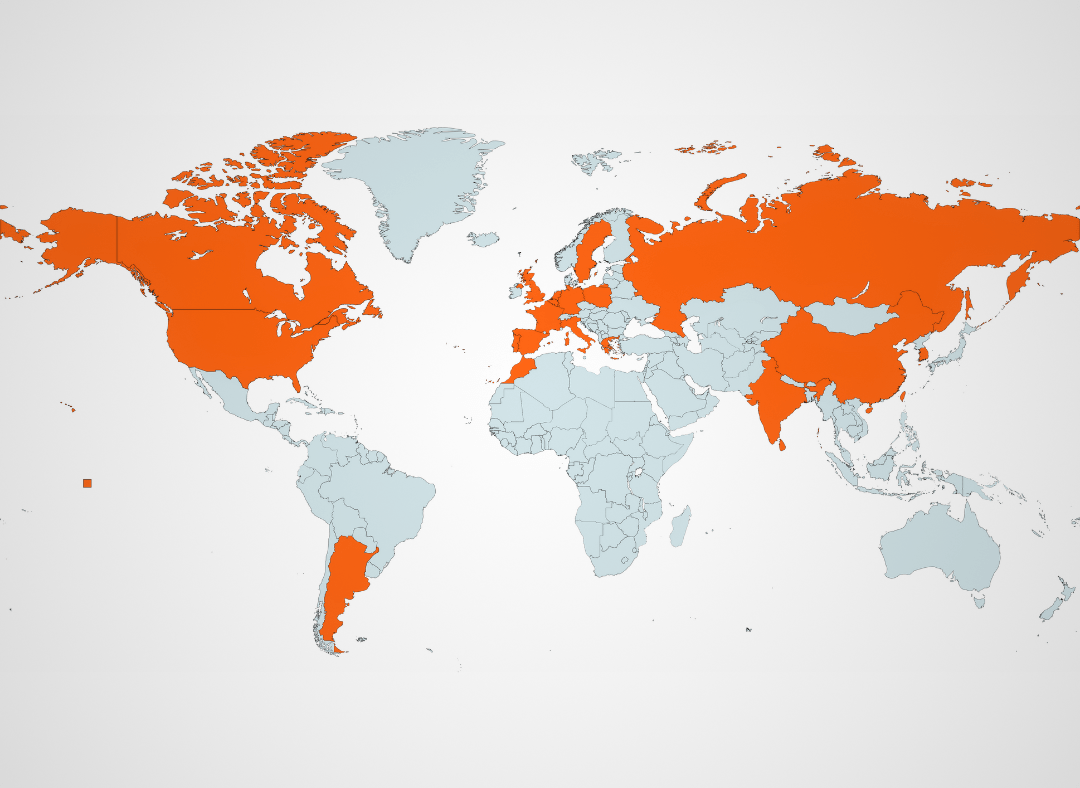

Réseau de distribution mondial

Présent dans plus de 20 pays. Que ce soit pour vous conseiller, un support technique ou une livraison rapide, nos distributeurs sont à votre écoute.

Ils nous font confiance

Les catégories les plus recherchées

Qui sommes nous ?

SDEC France, votre passerelle vers des solutions de pointe dans les domaines de l’eau, de l’agronomie, de la science du sol, du nucléaire et de l’environnement. Fondée en avril 1991, nous sommes une entreprise pionnière située à seulement 30 km au sud de Tours, en Indre-et-Loire.

Notre mission ? Concevoir, fabriquer et fournir une gamme éclectique d’équipements qui établissent les normes de l’industrie. Notre usine ultramoderne de 2 000 m² est le centre névralgique de l’innovation, nous permettant de vous proposer le meilleur en matière de solutions d’instrumentation et de mesure. Nous accordons une grande importance à la protection de l’environnement et à la durabilité, des valeurs qui façonnent à la fois nos produits et nos pratiques. Rejoignez-nous dans cette démarche vers un avenir plus vert. N’hésitez pas à nous contacter pour toute demande. Ensemble, faisons la différence !

Etudes · Conception · Installation sur site · Maintenance · Formation

Expert en radioprotection

Découvrez l’expertise de SDEC France en matière de radioprotection, une véritable référence dans la surveillance radiologique. Nos solutions sont au cœur de la sécurité environnementale, car nous concevons et fabriquons des instruments de pointe :

- De mesure de tritium, carbone 14

- D’échantillonnage d’air, d’aérosols et d’iodes

Notre engagement envers nos clients va bien au-delà de la fabrication de ces instruments. Dès le début de votre projet, notre équipe est à vos côtés pour vous conseiller, concevoir des solutions sur mesure, assurer l’installation sur site, et garantir la maintenance de votre équipement en plus d’une formation complète pour assurer une utilisation optimale de nos produits. Avec SDEC France, vous avez accès à un ensemble de services complets allant des études à la formation, pour une radioprotection de qualité inégalée.

Partenaires mondiaux pour les solutions SDEC en radioprotection

Bienvenue dans le monde de SDEC France, leader des solutions environnementales et scientifiques pour la radioprotection dans plus de 21 pays. Nos partenaires de distribution soigneusement sélectionnés, couvrant l’Europe, l’Amérique, l’Afrique et l’Asie, partagent notre engagement pour la qualité, l’innovation et la préservation de l’environnement.

Nos distributeurs autorisés sont votre ressource de confiance pour accéder à nos instruments de pointe. Que ce soit pour des conseils d’experts, un support technique ou une livraison rapide, notre réseau mondial est à votre service. Avec nos partenaires de confiance, nous contribuons à l’innovation environnementale et scientifique à travers le monde.

Actualités

Pour surveiller efficacement les algues bleu-vert, utilisez des bouées avancées avec des sondes détectant les premiers signes d'algues et fournissant des alertes immédiates.

Participez à notre questionnaire pour découvrir le débitmètre acoustique idéal, adapté à vos besoins spécifiques.

Après une analyse approfondie des différentes techniques, y compris l'échantillonnage à haut débit, l'échantillonnage passif (sans débit) et d'autres, le grand gagnant est l'échantillonnage à faible débit.

Découvrez tout ce qu'il faut savoir sur SDEC en explorant notre section 'À propos' dès maintenant.

Plus de 30 annés d'expertise

et innovation pour un

environnement protégé. Explorer notre catalogue.

Optez pour l'efficacité et la fiabilité avec nos pompes immergées 12V Proactive, conçues pour des performances optimales. Distributeur officiel.

Offres du jour

Se termine dans

Inscrivez-vous à notre newsletter

Soyez le premier à recevoir des informations importantes sur l'instrumentation et les services associés pour la surveillance environnementale.

[mc4wp_form id="436"]

Livraison Rapide

Service dédié

Suivit projet A à Z

Étude, maintenance, mise en place et plus encore

Paiement Securisé

Transaction sécurisée à 100%

Support Expert

Service client spécialisé

Meilleurs marques

Produits choisis pour leur haute qualité

Comment pouvons nous vous aider ?

Nos experts sons disponibles pour repondre à vos questions