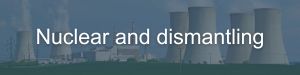

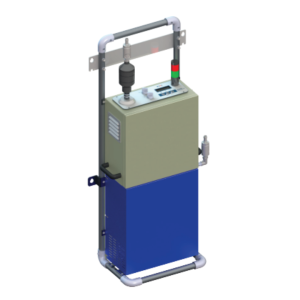

HAGUE 7000 – Carbon 14 Bubbler with 4 Pots (with Oven)

- OPTIMAL MONITORING OF CARBON 14: The HAGUE 7000 effectively monitors atmospheric C14, capturing gas and organic compounds from various sources.

- ADVANCED OPERATING PRINCIPLE: Uses bubbling in a soda solution to trap gaseous C14 and similarly oxidizes organic C14.

- PRECISE MEASUREMENT: Accurately determines the volumetric activity of C14 in the air, with a 100% trapping efficiency for CO2 and 94% for CH4-CO2 conversion.

- COMPLIANCE WITH STANDARDS: Designed according to NF ISO 20041-1 standards for maximum efficiency and ergonomics.

- OPTIONAL COOLING FUNCTION: Cooling system available, maintaining the trapping solution at 7°C for consistent performance.

- CERTIFICATION: NF ISO 20041-1

| APPLICATIONS |

|

· Nuclear Power Plants · Nuclear Research Centers · Radioactive Waste Storage and Treatment Sites · Laboratories · Incinerators · Decommissioning or any industries incorporating Carbon 14 |

– Very Limited Loss by Evaporation –

The HAGUE 7000 stands out for its impressive efficiency, with a CO2 trapping rate of 100% and a conversion of 94% of CH4 to CO2. This performance, confirmed by the GEA Study Report 12/2005, minimizes losses, particularly by evaporation, thus ensuring the reliability of the system.

– Applications of the HAGUE 7000 –

Ideal for detecting low levels of Carbon 14 in the air, the HAGUE 7000 is suited for air sampling from chimneys, hoods, rooms, and various environments.

|

|

| CO2 Trapping Efficiency | 100% |

| Oven Efficiency for CH4 > CO2 Conversion | 94% |

| Dimensions | L x H x P = 700 x 356 x 270 mm |

| Space Requirement | L x H x P = 1000 x 600 x 530 mm |

| Weight | 29 kg |

| Maximum Power | 700 Watts |

| Main Power Supply | 230 Volts 50 Hz (available in 110 Volts 60 Hz version) |

| Operating Temperature of the Bubbler | +2°C à +45°C |

| Storage Temperature of the Bubbler | -5°C à +70°C |

| Electrical Protection | Differential circuit breaker (30mA) and slow-blow fuse (6A) |

| Display | Backlit LCD Screen |

| Frame | Monocoque chassis in aluminum alloy, bright blue leather grain RAL 5010 decontaminable epoxy powder paint |

| Power Cord | Supplied with IEC plug power cord, four pots and caps, calibration certificates, and user manual |

– Official Supplier –

Various nuclear power plants in Europe and worldwide.

– About SDEC –

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

SDEC is your global partner for SDEC solutions in radioprotection. Welcome to the world of SDEC France, a leader in environmental and scientific solutions for radioprotection in over 21 countries. Since 1991, SDEC France has been designing, manufacturing, and marketing a wide range of equipment for environmental study and monitoring.

– FAQ –

The pressure regulator is primarily used when the bubbler is connected to a pressurized device.

The device is equipped with a cooling circuit that maintains the trapping solution at an average temperature of 7°C (for an ambient temperature of 20°) and thus prevents the loss of the sample solution by evaporation. This option is essential for weekly or longer duration sampling.

The design and efficiency of the system ensure very limited loss, particularly by evaporation, making the sampling process both reliable and effective.

Yes, the HAGUE 7000 is designed to operate efficiently in different conditions, ensuring reliable measurements regardless of the environment.

Yes, the efficiency and performance of the HAGUE 7000 are certified by the GEA Study Report 12/2005.

The HAGUE 7000 displays a 100% trapping efficiency for CO2, and its oven achieves a 94% conversion rate of CH4 to CO2, making it very precise in detecting Carbon 14 levels.

The sampling is versatile and can be used to sample air from various sources, including chimneys, hoods, rooms, and the general environment.

Additional information

| Dimensions | L x H x P = 700 x 356 x 270 mm |

|---|---|

| Size | L x H x P = 1000 x 600 x 530 mm |

| Weight | 29 kg |

| Maximum Power | 700 Watts |

| Mains Power Supply | 230 Volts 50 Hz (available in 110 Volts 60 Hz version) |

| Operating Temperature of the Bubbler | +2°C à +45°C |

| Storage Temperature of the Bubbler | -5°C à +70°C |

| Electrical Protection | Differential circuit breaker (30mA) and slow-blow fuse (6A) |

| Display | Backlit LCD Screen |

| Débit d’air normalisé réglable | 10 à 50 NL/h |

| Réglage de la température de normalisation | de 0°C à 25°C |

| Régulation du débit d’air | automatique |

| T° du four réglable | 200°C à 500°C |

| Extras | Admission et échappement inox Ø 6,4 mm |

| Applications | Dismantling or any industries incorporating carbon 14, Incinerators, Laboratories, Nuclear Power Plants, Radioactive Waste Storage and Treatment Sites, Research on the Impact of Different Contamination Levels |

Reviews

There are no reviews yet.